Cut and puncture gloves

The toughest, most durable PPE on the market

Some workplaces require more protection – they demand the strongest, toughest, and most resilient safety gloves. Built to handle the most extreme occupational hazards, HexArmor® heavy-duty gloves are built from the inside out, with proprietary technologies that provide industry leading cut and industrial puncture resistance.

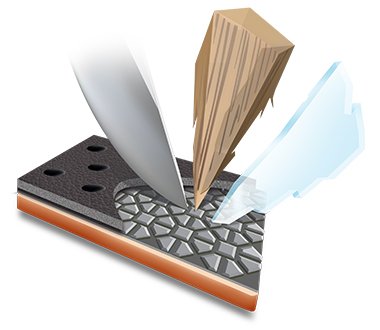

SuperFabric® brand materials are engineered to deflect and block everything from industrial puncture hazards as thick as a wood splinter, to a single wire strand from a steel braided cable. The spacing between the guard plates provides needed flexibility without sacrificing performance.

HexArmor® gloves, arm, and body protection made with SuperFabric® are engineered to arrest and deflect everything from industrial puncture hazards as jagged as a wood splinter, to a fine single wire strand from a steel braided cable. Small guard plate geometry traps and blocks the hazard, providing flexibility while preventing a puncture from reaching the skin, an event that could lead to a laceration.

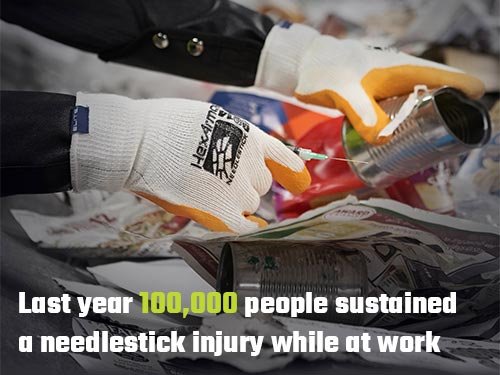

Needlestick resistance

HexArmor® needlestick-resistant products work by layering flexible SuperFabric® brand material over each other; providing superior performance without sacrificing dexterity. SuperFabric® guard plates either block and deflect or trap and arrest needle hazards in the small gaps found between guard plates, keeping workers safe from needlestick injuries.

The prevalence of needlestick punctures in the recycling and waste industries, as well as the emergency services is steadily increasing. Without proper protection, workers are susceptible to life-changing needlestick injuries that can lead to bloodborne pathogens, including hepatitis B, hepatitis C and HIV.

SuperFabric® offers industry-defining needlestick protection. And, unlike most other needle-resistant technology, you don’t see a dip in other protective properties when you choose HexArmor PointGuard® products. HexArmor needlestick-resistant products also boast some of the highest cut resistance in the industry.

High-flex impact protection

Not all impact gloves are created equal

Stay prepared and protected from impact, smash, and pinch hazards with the most advanced technology on the market. Tested and updated under the ISEA 138 impact protection guidelines, HexArmor’s lineup of impact-resistant products feature three proprietary technologies that are proven to reduce the number and effects of injuries during sudden impacts. These cutting-edge technologies swiftly absorb and redistribute energy away from the hand and fingers during an impact, while simultaneously offering more comfort and dexterity than any other impact-resistant technology on the market. Featured on several HexArmor® glove styles, this is the next generation of impact protection.

For additional impact protection, HexArmor offers Cellutek® impact technology. Made from a proprietary material, Cellutek® is a full back-of-hand impact protection system that’s sewn into the glove. The impact absorbing properties layered with thermoplastic rubber (TPR) impact material dampens blunt forces, dissipating the blow from the impact.

Contact heat and Arc Flash protection

Gloves are a crucial piece of PPE for electrical workers and need to consist of high dielectric and physical strength, with flexibility and durability to mitigate the impact of an arc flash. The below gloves have been certified using the ANSI arcman test in accordance with ASTM F2675 and PPE selection standard NFPA 70E. The gloves are Categorised as Cat II Intermediate PPE under EU regulation 2016/245. These ratings are based on Hazard Risk Category (HRC) standards and the Arc Thermal Protective Value (ATPV). HRC is the safety standard that shows the minimum amount of PPE protection a worker needs based upon the potential exposure to a hazard, ranging from 0 to 4, with 4 being the highest risk. ATPV is the incident energy needed to cause a second-degree burn; this value is provided in calories per centimetre squared (cal/cm²).