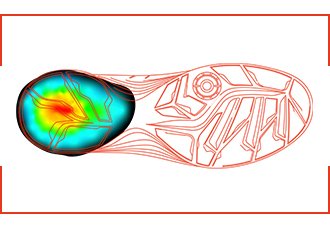

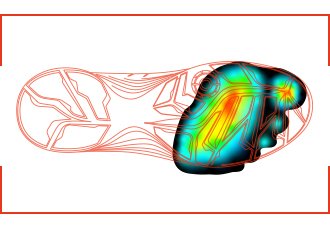

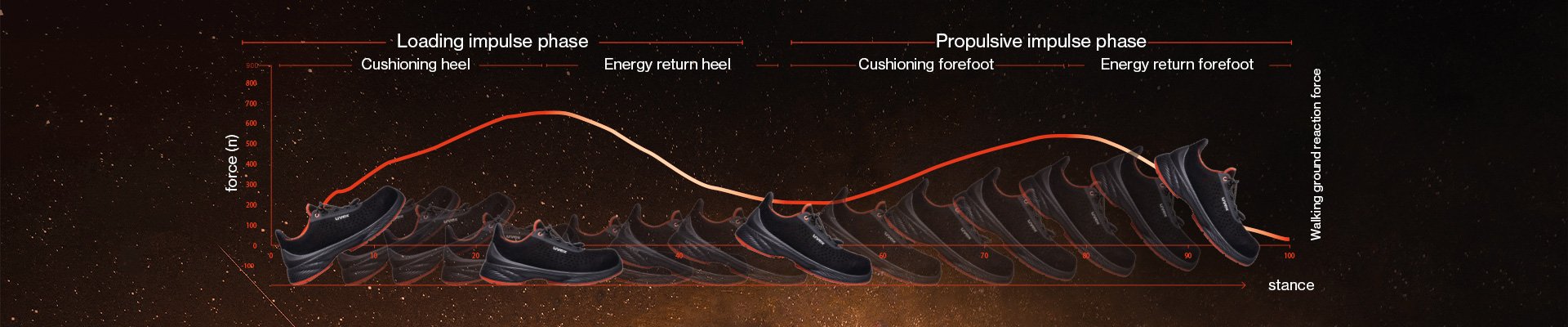

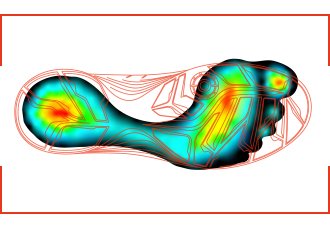

The uvex i-PUREnrj two-layer outsole is made of a newly developed type of polyurethane. The midsole has an energy absorption of 40.8 joules, (i.e. double that required by the standard) while providing energy recovery of around 66% in the heel* and 59% in the forefoot*.

*Test report no.: L190714889 CTC Lyon — 22/08/2019

Cushioning after

1000km

29%

higher cushioning after 1000km use compared to standard polyurethane soles.*

Less fatigue. More comfort. More performance

21%

less perceived fatigue compared to standard polyurethane soles.

Increased stability

More Stability.

Reduced Risk of Injuries.

More Safety.

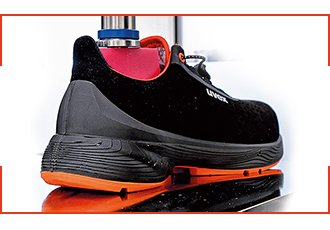

Excellent stability and secure fit in the shoe due to foamed heel basket and adapted density of the uvex i-PUREnrj technology.

uvex x-tended grip Technology

100% performance. Greater safety and stability. Longer life.

The uvex x-tended grip technology, based on the latest generation TPU outsole, guarantees even greater slip resistance across the whole outsole surface including when worn on smooth or wet surfaces. It also delivers even more abrasion resistance when compared to the standard, making them particularly durable. As a result the wearer experiences greater safety, stability, less wear and consequently lower costs thanks to a longer service life.

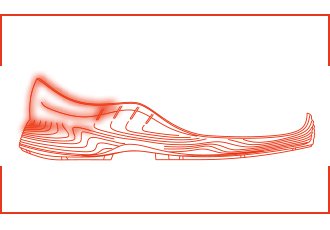

The coloured blocks in the heel (strike) and toe area (push off), provide additional grip as this is where there is typically the highest amount of abrasion.

Less abrasion ensures a longer life

Abrasion resistance with

uvex x-tended grip

66%

more abrasion resistance than required by the standard

Improved abrasion resistance in

high wear zones (the heel and toe)

33%

more abrasion resistance compared to the standard = product durability and longevity

Improved abrasion resistance

in 3 zones

1. TPU material and rubber modifier

2. TPU material

3. TPU material and rubber modifier

The TPU sole and rubber modified coloured zones (where there is typically more wear) have been produced to ensure the tread stays sharp edged for longer and is more slip resistant improving safety and stability.

The tread of the outsole with uvex x-tended grip technology has been specifically adapted to working on industrial floors. Shaped in accordance with the latest findings from biomechanical research and using the latest generation of TPU, the sole of the uvex 1 G2 is guaranteed to deliver even greater abrasion resistance and slip resistance on smooth or wet surfaces. The result? Greater safety and stability for the wearer; less wear and, consequently, lower costs thanks to a more durable, longer service life of the footwear.

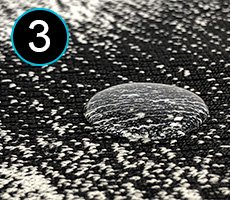

uvex x-dry knit Technology

100% performance. 100% wearer comfort. 100% dry feet.

The unique uvex x-dry knit technology offers unparalleled levels of comfort by keeping feet dry and comfortable throughout an entire day thanks to the intelligent combination of outstanding breathability and water-repelling characteristics. Independent tests at PFI Pirmasens Test and Research Institute have proven the unique performance of the uvex x-dry knit technology.

Water vapour permeability

40x

more breathable than the minimum requirement of EN ISO 20345

Water vapour coefficient

17x

more breathability and absorption in the material than the minimum requirement of EN ISO 20345

Water penetration

100%

more water resistant than the minimum requirement of EN ISO 20345

Water absorption

10x

more than the minimum requirement of EN ISO 20345

Discover the range

The new uvex 1 G2 range features uvex’s innovative polyurethane sole technology uvex i-PUREnrj to return the landing energy back to the wearer, uvex x-tended grip technology for even more stability and slip resistance, and the unique uvex x-dry knit technology for outstanding breathability and water-repellent characteristics. Available in S1 P, S1 and S3, and as either a shoe or a boot, the uvex 1 G2 has something for everyone.

![Joule [J] energy absorption Joule [J] energy absorption](https://d3rbxgeqn1ye9j.cloudfront.net/images/VVNHfm8WeznMpkn8Rg8aiCtrwKETgraw9vP5eeRARyk/w:330/h:230/fn:Y3NtXzM1MC1jdXNoaW9uaW5nLWpvdWxlLWdyYXBoXzhmM2VmYTNhNDQ:t/cb:1f1cef87c545bbb8d6653d4c680b2ca808b5c508/el:1/fq:jpeg:85:avif:70:webp:80/aHR0cHM6Ly9kM3JieGdlcW4xeWU5ai5jbG91ZGZyb250Lm5ldC9maWxlYWRtaW4vd3d3LnV2ZXgtc2FmZXR5LmNvLnVrL01lZGlhL2Zvb3R3ZWFyLzM1MC1jdXNoaW9uaW5nLWpvdWxlLWdyYXBoLmpwZz8xNjY4MTYwODA4)