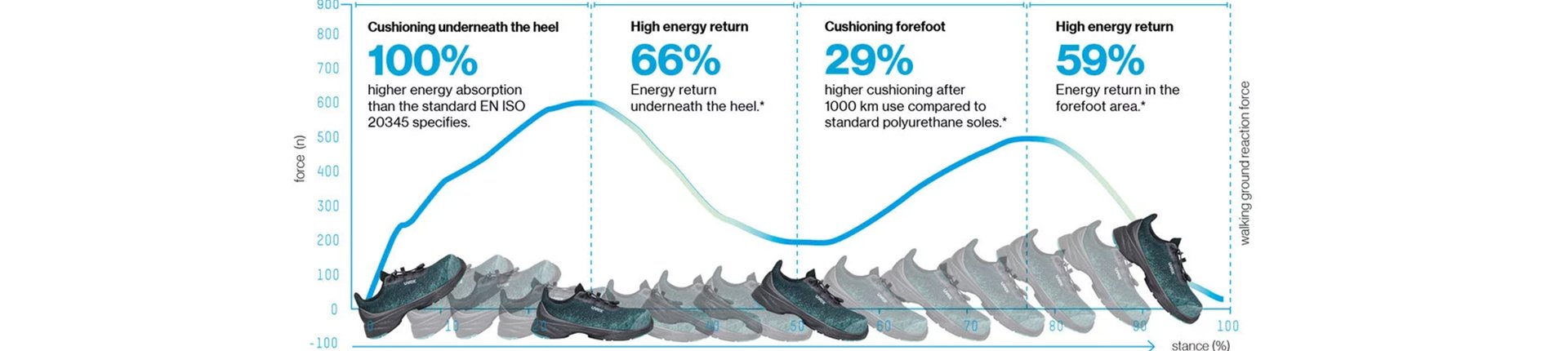

uvex i-PUREnrj technology

- Outstanding shock absorption properties at the forefoot and heel

- Excellent rebound energy over the entire midsole

- Foamed heel basket provides excellent stability and reduces the risk of injury

- uvex x-tended grip planet TPU outsole with up to 10% recycled PU waste from our production processes

uvex xenova® toe cap

- 100% metal-free

- Compact design

- Anatomical shape

- No thermal conductivity

- TPU scuff cap made from 40% recycled polymers, protects the upper for longevity

Penetration-resistant midsole

- Metal-free, penetration-resistant midsole made from 100% recycled material

- Removable antistatic comfort insole made from 100% recycled PET bottles and foam consisting of recycled PU production waste and recycled PU

- Does not restrict the flexibility of the shoe

uvex x-dry knit

- Virtually seam-free construction to eliminate pressure points

- uvex x-dry knit planet material made from 100% recycled PET bottles

- Breathable lining made from 18% bamboo and 52% recycled polyester

Midsole innovation: i-PUREnrj planet

uvex is the first company to have succeeded in using the direct injection process to integrate granulate made using polyurethane waste from production processes into the midsole of a safety shoe, and then to launch the fully-certified product on the market. This allows us to utilise less raw materials and to return PU waste to the shoe production cycle, without compromising the performance of our i-PUREnrj technology, which provides cushioning and energy return across the entire sole of the foot, helping reduce wearer fatigue.

protecting planet

To help raise awareness of its commitment to achieving increased sustainability, uvex has developed the protecting planet label.

For uvex, protecting planet is more than just a marketing slogan. Based on our brand claim, protecting people, our sustainable approach integrates three core pillars — ecology, economy and social responsibility. These are incorporated throughout the business to improve our sustainability performance. This is why uvex undertakes comprehensive audits, measurements and evaluation management processes along the entire value creation chain to ensure our products are as sustainable as possible.

- Upper part of the safety shoe is made from 100% recycled polyester made from PET bottles

- Penetration resistant midsole is also made from 100% recycled materials

- 40% recycled TPU is used for the TPR scuffcap

- Distance mesh lining is made from 52% recycled polyester and 18% bamboo fibres

- Replaceable comfortable climatic insole is also made of 100% recycled PU foam and polyester

- All uvex shoe boxes are made from 90% recycled cardboard

- 100% recycled tissue paper is used to package the shoes

- Instructions for use are made from 100% recycled paper (It is an EU regulatory requirement to provide printed user manuals to inform users of the intended purposes, proper usage, potential hazards, and other relevant information about a product.)

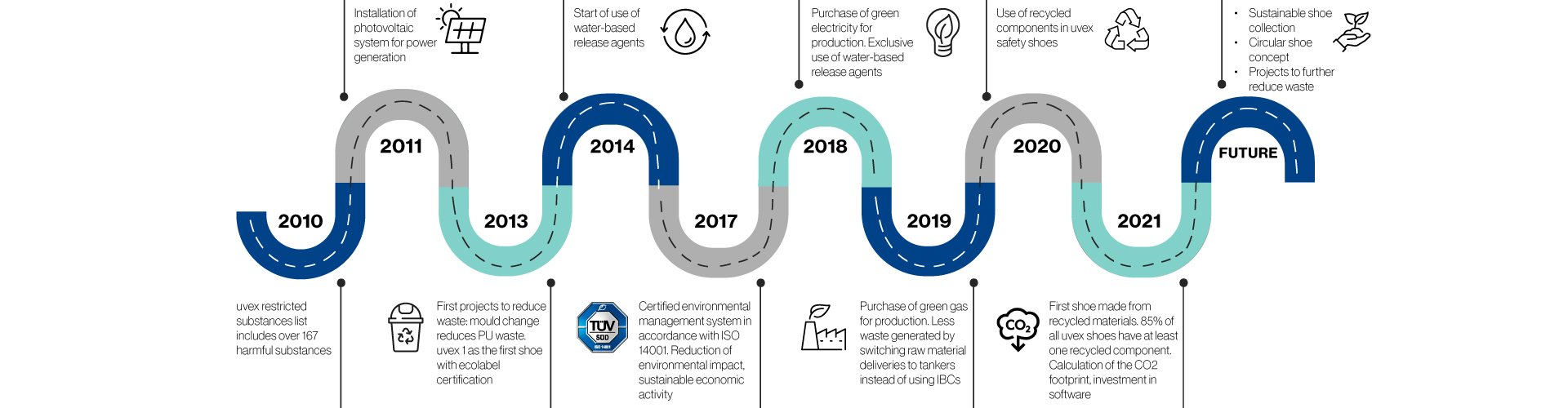

- The uvex plant in Ceva, Italy, uses green electricity and green gas and is certified according to the environmental management system ISO 14001

- The plant uses renewable energy with a photovoltaic system

- Some years ago, the shape of the soles were redesigned to significantly reduce the amount of waste

- All PU waste is collected and processed into granuals ready for reuse

- Up to 10% recycled PU waste from uvex’s production is used for the TPU outsole of the uvex 1 G2 planet

The production in Italy, which is one of the most modern production facilities for safety shoes in Europe, ensures efficient, resource-saving production and short distances from manufacturer to user.

Sustainability at uvex footwear

"For over 90 years, we have been producing and distributing high-quality products to protect people in sports, leisure and at work. Any company wanting to protect people must accept the responsibility that comes with it. It is exactly this mission that instils our commitment to work sustainably and with social responsibility."

Michael Winter, Managing Partner of the uvex group

uvex competence center for safety footwear in Ceva, Italy

Development expertise, state-of-the-art robot-controlled production systems and optimised process structures to meet the highest ecological standards guarantee the first-class and sustainable quality of our safety shoes.

The production in Italy, which is one of the most modern production facilities for safety shoes in Europe, ensures efficient, resource-saving production and short distances from manufacturer to user.

- Production of direct-injected safety shoes with outsoles made of polyurethane, thermoplastic polyurethane and rubber

- Innovative production technologies, e.g. for using rebound properties

- Four DESMA direct-injection machines for producing uvex outsoles, three of them with DESMA AMIR system (automated material handling with integrated robots)

- Extensively equipped test laboratory for quality and production assurance and for product development

Step 1

Removing the PU waste from the finished shoe

Step 2

Reducing the surplus PU production waste to granulate

Step 3

Absorbing and mixing the granulate into the PU compound

Step 4

Direct injection soling using PU material including granulate